Dental Labs

Why soldering remains important in dental technology

Ivoclar Vivadent

How often do you solder? Have you ever asked yourself how important soldering is in the overall context of dental laboratory work – and which requirements are essential to achieve a successful soldering result? If you have, then you may find this background information insightful. Come with us on a journey through the past, present and future of the (dental) soldering technique!

Soldering: indispensable in the dental lab

“Soldering” as a joining technique is an essential aspect of everyday work in the dental lab. In dental technology, soldering has been used for over a hundred years – the method of soldering, however, has been known for much longer than that. Soldering was practised even in antiquity. The soldering methods of those days involved copper ore and helped goldsmith to design intricate pieces of jewellery.

Soldering is the most common method used to join metal materials and the principles on which this technique is based will not change in the future.

In spite of modern welding and bonding techniques, soldering has not lost its importance in dental technology due to its universal range of applications. In the dental lab, the daily number of soldering processes still clearly exceeds the number of other joining methods.

What is soldering?

During the soldering process, the liquid solder and solid-hot alloys undergo a process of mutual diffusion. The bond strength (= quality of diffusion structure) and resistance to corrosion are the decisive factors for the long-term success of the solder joint.

Solders: Resistance to the oral environment is essential!

Solders are classified into high-fusing solders having a melting range between 950 and 1,200 °C and low-fusing solders with a melting range between approx. 700 and 900 °C. The different melting ranges accommodate different purposes. It is important that the solders and alloys are compatible with each other. A high degree of care is required to achieve a reliable solder joint. An understanding of the materials involved in the soldering process and knowledge of how to apply them correctly form part of a careful approach to soldering.

Below follow the most important requirements for successful dental soldering:

1) Compatibility of metals

The solders selected for the soldering process should have a processing temperature that is suitable for the alloys to be soldered. Dental solders must be resistant to the oral environment and their composition must be similar to the composition of the alloys being soldered. This means that (metallurgical) compatibility and similar coefficients of thermal expansion of solders and alloys are prerequisites for achieving a reliable solder joint.

2) Effective wettability

The solder’s capability of effectively wetting the alloy is another requirement for a successful soldering process. If the solder has ideal wetting properties, it spreads out evenly on the alloy, wets both surfaces and fills the soldering gap. If the solder has poor wettability, it forms droplets. In this case, the solder does not flow and diffusion does not occur; or in other words, the metal compounds contained in the alloy and the solder fail to intermix. An ideal diffusion structure forms if the difference between the processing temperature of the solder and the solidus point of the alloy is minimal.

3) Clean metallic surfaces

Clean soldering contact surfaces are a basic requirement for adequate wetting. The contact surfaces should be free of grease and oxide. Grinding and/or sandblasting can be used to prepare the soldering contact surfaces.

4) Oxide-dissolving flux

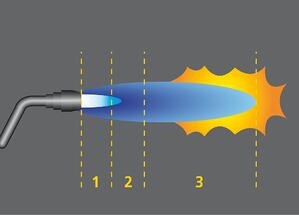

It is advisable to use a flux to prevent the formation of oxide. The flux dissolves the oxygen compounds on the surface of the alloy. During the dissolving process, the flux absorbs the oxides and prevents any further oxidation from occurring. The soldering process should be completed immediately after the application, as the solubility of the oxides captured in the flux is limited. This process is assisted by using the “reduced zone” of the flame.

5) Evenly pre-heated framework components

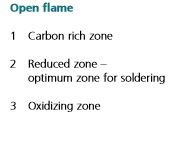

6) Soldering gap walls should be as parallel as possible

Only if the walls of the framework components are parallel to one another is the solder pushed into the soldering gap by the pressure being released (capillary filing pressure). The walls should be aligned at an even gap from one another at a width of approx. 0.05 mm to no more than 0.2 mm.